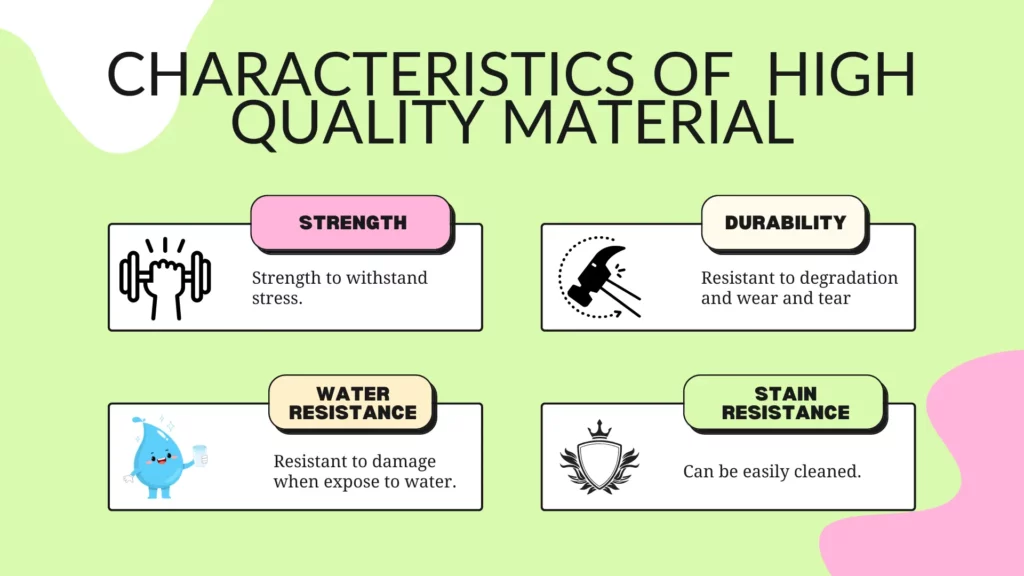

In order to guarantee that our products meet or exceed the expectations of our customers, we must use only the highest quality materials available. Strength, durability, water and stain resistance are just a few of the key features that make up a quality material. Ensuring that only the finest materials are employed in production is critical for producing top-notch products.

What Are The Characteristics Of A High Quality Material

When it comes to manufacturing quality products, choosing the right material is of paramount importance. High quality materials are those that possess a variety of characteristics that make them suitable for their intended uses. For instance, the strength, durability, and water resistance of a material often determine its quality and usability in certain applications.

Strength is a major factor when determining the quality of a material. The stronger the material, the more resistant it will be to damage or wear. This quality is especially important when making items such as tools, furniture, or automotive parts which need to withstand some level of stress without breaking or becoming damaged over time. Strength also plays a role in how well the product will perform during its intended use – if it’s too weak then it won’t be able to do its job properly. Different materials may have different levels of strength depending on their composition and desired end-use application so materials should always be chosen accordingly.

Durability is another quality that is important for high quality materials. The more durable a material is, the longer it will last before needing replacement or repair – saving money in terms of maintenance costs over time or providing assurance that products made from them can stand up to everyday use. Durability can even refer to how long a product retains its color, shape, or form – this quality is particularly important when creating items meant to look good for long periods such as clothing or housewares products.

Water resistance is yet another quality of high quality materials that makes them desirable for many types of applications – water-resistant materials are highly sought after due to their ability to keep out moisture and protect items from rusting or corroding over time. Even relatively small amounts of water seepage can cause great damage if left unchecked and so having a water-resistant material on hand can help prevent disaster in these situations. Similarly, stain-resistant materials can be valuable assets when making items such as furniture which need regular cleaning but may easily become stained by liquids if not properly protected beforehand.

The Importance Of Using High Quality Materials

The importance of using high-quality materials in manufacturing cannot be overstated. High-quality materials have a direct effect on the safety, reliability, and durability of the final product. Not only do these materials protect against potential hazards, but they are also more cost-efficient and can help to reduce production costs in the long run.

Strength is one of the most important qualities of high-quality material. It needs to be able to withstand environmental conditions and continue performing optimally without fail over long periods. Durability is another essential component: with high-grade materials, products last longer and require fewer repairs or replacements down the line.

Water resistance is another key component for any material used for manufacturing purposes. Products that are exposed to moisture will corrode quickly if not properly protected by quality materials. Stain resistance also plays a role in keeping products looking new for longer periods as well as ease of cleaning and maintenance.

Materials used in manufacturing must also be low-maintenance, economical, and easy to source. Poor quality materials can be costly to repair or replace and can create potential safety risks if they are not up to standard. Quality materials are also more versatile; they can be used in different ways than lower quality ones might not be able to handle efficiently due to their inferior strength or durability characteristics.

High-quality materials help create better products while reducing waste, environmental impact, and operational costs over time as well as improving customer satisfaction with the product’s performance. By investing in higher quality material upfront companies can typically save money down the line when it comes time to maintain or replace parts due to wear and tear or wear out prematurely due to poor quality construction initially. Therefore, investing in quality materials can lead to increased productivity, improved efficiency, and higher profits for companies that use them for their manufacturing processes.

How To Determine If A Material Is High Quality

When it comes to determining if a material is of high quality, several key characteristics should be taken into account. Strength and durability are two of the most important factors. The material must be strong enough to withstand the pressures of usage, as well as be able to resist wear and tear for a long period. Water resistance is also an important trait when considering materials for manufacturing, as moisture can cause damage over time. Stain resistance is another quality that should be looked at, as some materials may not be able to repel certain substances or liquids. In addition to these key traits, other aspects such as chemical compatibility and heat resistance should also be considered when evaluating the quality of a particular material.

To verify that a material has the desired characteristics, various tests need to be performed by industry standards and regulations. For example, strength tests measure how much force a material can withstand before breaking or failing while durability tests measure how much wear and tear a material can handle before becoming unusable or weakened. Similarly, water resistance tests assess how impervious the material is against liquid seeping through or damaging its surface or structure. Tests for stain resistance examine what substances the material can repel without becoming damaged or discolored. Additionally, chemical compatibility testing reveals what sort of chemicals the material can tolerate without deteriorating or showing signs of corrosion over time due to exposure. Heat resistance tests determine what temperatures the material can withstand without being damaged or degrading too quickly.

By assessing each characteristic individually and making sure they conform to industry standards, manufacturers are then able to determine if a particular material is suitable for use in their products and processes. High quality materials are those that possess all of these traits in combination with one another to ensure product reliability and longevity over time.

The Benefits Of Using High Quality Materials To Manufacturer

Using high quality materials to manufacture goods and products can bring a range of benefits that are often overlooked. High quality materials are typically more durable and have greater strength, meaning they will last longer and be more reliable in the long run. Additionally, these quality materials often offer greater resistance to water and stains, ensuring that their quality is maintained over time. Furthermore, superior quality materials tend to be safer for use in manufacturing as they are less likely to contain hazardous substances or other contaminants.

High quality materials also provide greater aesthetic appeal when used in manufacturing products. The improved durability ensures that the product has a higher quality look and feel, and this can result in improved customer satisfaction. As customers recognize the quality of a product, they are more likely to purchase again from the same company in the future. In terms of cost savings, using high quality materials can help manufacturers avoid expensive repair costs due to premature failure or wear of cheaper materials.

For environmental considerations, quality materials can also offer an advantage over lower grade alternatives. Quality materials could contain fewer toxins or pollutants, which means less harm caused by emissions during manufacturing processes. This could further lead to reduced energy consumption that helps reduce global warming from excessive carbon dioxide emissions associated with production processes involving inferior grade material sources.

Finally, using high quality materials has implications beyond just a manufacturer’s production process – it has implications for human health too! Lower grade material components can be known to release dangerous toxic particles into the air which can cause serious respiratory issues for workers within the factory environment who may be exposed on a daily basis without proper ventilation systems – but if quality materials are used instead then such risks can generally be avoided!

Conclusion

All in all, investing in quality material sources has many advantages – it provides increased safety for workers on site who handle these components regularly; it increases product durability and thus enhances customer satisfaction; it reduces overall costs associated with repairs; it helps conserve resources by reducing energy requirements; and most importantly it contributes towards better environmental stewardship by providing cleaner air pollution standards!